First to foam

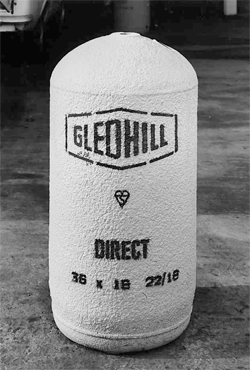

Foam insulation was introduced to the manufacturing process of  domestic hot water cylinders in 1965. Gledhill was the first cylinder manufacturer in the UK to introduce this. It was applied electrostatically by the Ransberg Disc method.

domestic hot water cylinders in 1965. Gledhill was the first cylinder manufacturer in the UK to introduce this. It was applied electrostatically by the Ransberg Disc method.

Lightweight cylinders

The launch of the first all weld lightweight cylinders came in 1967. These were produced in both copper and stainless steel using the revolutionary circumfrential welding technology. These cylinders were the forerunner of today’s EnviroFoam Stainless vented cylinder range, manufactured from 0.5mm stainless steel. This lightweight philosophy is also used in the StainlessLite unvented range of cylinders. They are manufactured from 0.6mm stainless steel, at least 30% thinner, and ultimately lighter, than other stainless steel unvented cylinders on the market

State of the art

In 1973 Gledhill expanded into its new 70,000 square feet, state of the art manufacturing centre in Blackpool. This allowed the company to meet demand for 4000 domestic cylinders per week, including commercial vessels which ranged up to 10,000 litres capacity.

Local manufacturing depots

By 2000, Gledhill had its main manufacturing plant in Blackpool, but in addition, it had a network of manufacturing depots stretching from Inverkeithing in the north to Paignton in the south. This became a unique attribute for Gledhill, and has continued to develop into the effective distribution network of today.

Their unique structure, consisting of five distribution hubs, is geographically situated for effective, widespread product availability. Headed by a central sales and logistics team at their Blackpool headquarters and transported via their own fleet of Gledhill vehicles, they have ultimate control over the delivery of their products, enabling them to add value to their customers, meet demanding orders and high service expectations.